Technical speciation:

Maximum unwind width 1500mm

Maximum unwind diameter 1300mm

Maximum rewind diameter 1300mm

Speed ≤250m/min.

Applicable paper grammage 110~600g/㎡

Number of cutting blades 17 sets up-and-down blades

Power source requirement 380V,50HZ

Air supply requirement 0.3~0.4Mpa clean compress air

Main motor power 15KW

Clamp motor power 1.1KW*2 sets

Power of waste paper sucking blower 3KW

Speed regulating system Frequency conversion

Electric operation components China chint

Electric signal components Autonics

Pneumatic elements Airtac

Parent roll loading Pneumatic

Rewind reels unloading Pneumatic

Brake device Double dish braking

Rewind shaft Air shaft

Paper reels seperating Banana shaft

Rewind method Surface rewinding

Material of driving shaft Polyurethane

Separated electric control box 1

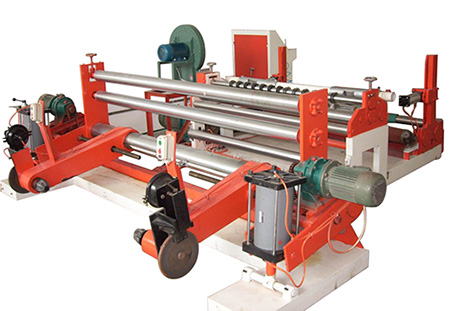

Main machinery dimension 3200*3200*1200mm

Main machinery weight 3300 KGs

Operator 1-2

Machinery warranty period 12 months

Tool box 1 set free of charge

Machinery wearing parts

Name Working life Handling

Brake block After processing 200 tons paper Total 5 sets free of charge

Bladder of air shaft Over one year Total 1 pc free of charge

Blades Oe year The buyers should pay cost if need more

Machinery Features:

1) Loading the parent roll and unloading the rewind reels automatically, easy to operate.

2) Using banana shaft to separate the rewind reels easier.

3) Surface rewinding: good for paper tightness and tension during paper tube winding.

4) High-quality blades are good for slitting tolerance