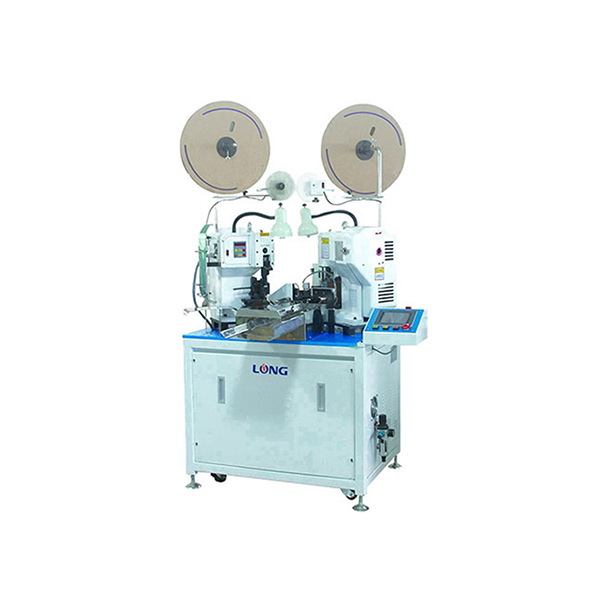

LLY-2D full-automatic terminal crimping machine is for wire cutting, stripping and both-end terminal crimping machine.

Product information:

The machinery outside-shell and parameter are designed with the international technologies. Fully automatic processing project includes wire feeding, cutting, end stripping and crimping.

Advantage: High-precision and high-speed for wire stripping and crimping

Including digital controlling and touch-screen.

PLC control, do not required wire pre-feeder.

Product specification:

1) Overall size: W1300*D1480*H1450 mm

2) Weight: 500 kg

3) Power supply: AC 220V

4) Compressed air: 0.5MPa (5Kgf/cm2)

5) Crimping capacity: 19600N (2.0 Tons) * 2 sets low noise type

6) Wire size: 0.05-0.8mm2 (UL1007AWG# 30-18) with OD.3.4mm

7) Capacity: 0.8 sec/pc (in case of min wire length)

8) Available cutting length: 30-- 9999 mm

9) Cutting tolerance: L100mm, +/- (1.0+0.002*L) mm

10) Available stripping length: Item 1: 1.0-10.0mm; Item 2: 1.0-17.0mm

11) Cutting depth: 2mm 100 steps (1 step =0.02mm)

12) Power consumption: 2.0KW

13) Detector: with or without wires, wire over-load, wire abnormal variation, pressure dropping, and abnormal wire stripping & crimping.

14) Machinery parts: 1) Use Taiwan Dongyuan motor and driver, more presious and stable; 2) Use Japan SMC and Taiwan Jingqi Pneumatic parts, more stable and durable, high-efficiency; 3) Use Switzerland Bel 5.7' colourful touch screen, easy to control; 4) Use Japan THK guide-rail, more stable and durable; 5) Use Japan Omron detecting elements, more precisious and stable; 6) Use Taiwan brand PLC, stable and precisious to control .